Rip saw

JRIMAC rip saw STANDARD

Classic.

Simple.

Good.

Rip saw

JRIMAC rip saw STANDARD.

The STANDARD is used wherever boards, planks, panels and beams are to be processed. Other materials such as sandwitch panels with plastic or aluminium coating, aluminium, plastic or composite panels (ALUCLIBOND or similar) also pose no problem for the rip saw. Whether for small, medium or large companies, the JRIMAC STANDARD scores with its optimum timber yield and cutting quality. Economical operation is guaranteed by its ease of use.

Longitudinal rip saw

JRIMAC rip saw STANDARD

Classic. Simple. Good.

- Max. cutting height: 150 mm (optional 175mm)

- Max. cutting length: 4200 - 6200mm

- Max. cutting width: 420 - 2120mm

- Saw motor: 11 kW (optional 15kW)

- Equipment line: STANDARD Line

STANDARD line.

The features.

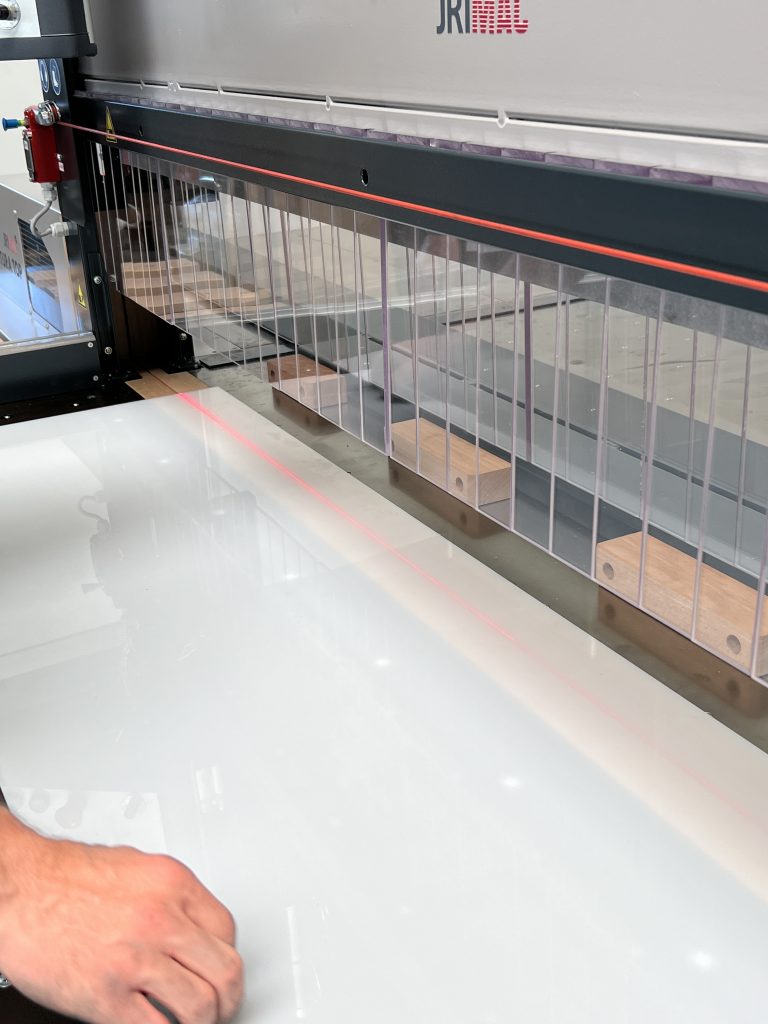

- Precise and clean cut

- Cutting direction left - right/ right - left

- Flexible and efficient working.

- Forced-guided pneumatic hold-down device with zero cut device.

- Various options for the cut release

- Convenient semi-automatic saw blade height adjustment

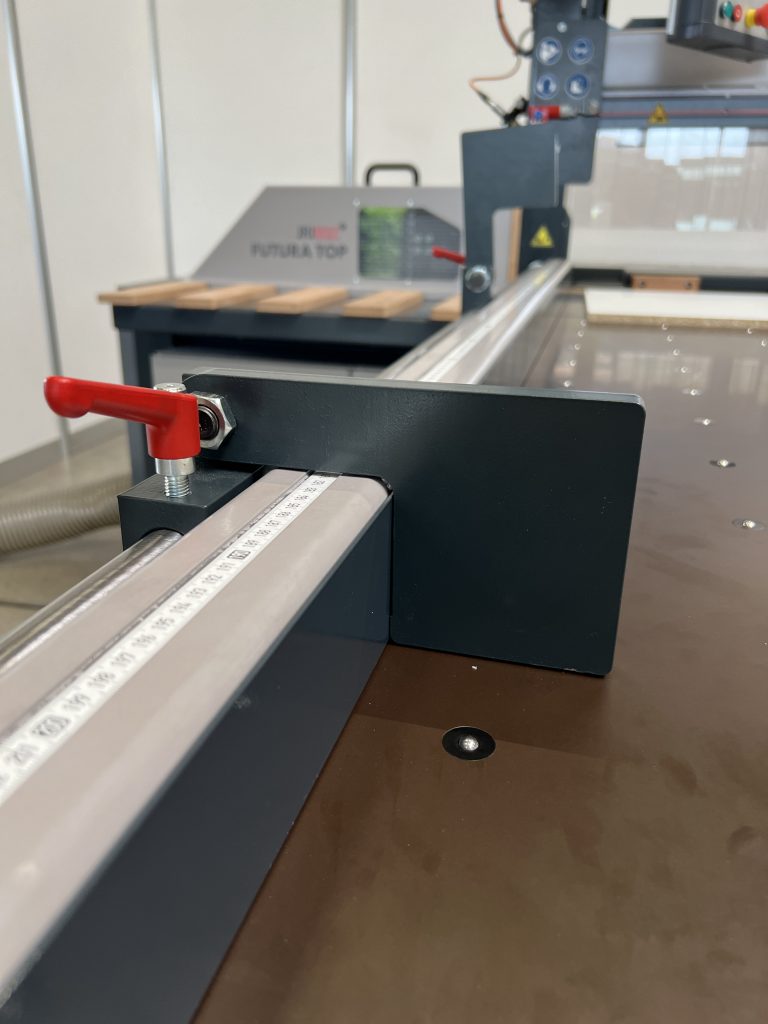

- Stepless adjustment of the width stop

- Electronic positioning control

- Saw blade quick clamping system "JRIMAC"

- High work safety

- User-friendly

- Cutting accuracy +/- 0.5 mm

Q & A. - The most important answers to your questions.

- 100% produced and assembled in Germany. Guaranteed quality.

- Over 30 years of know-how and experience in the field of sawing technology. You benefit from our expertise.

- Versatile areas of application. Processing of 12 materials possible.

- High-quality vendor parts from German manufacturers for long-lasting performance.

- Certified machine, CE-compliant.

- Customized solutions - special machine construction is possible on customer request.

- High-value retention and excellent resale values. Even after decades.

- Minimal training is required thanks to an intuitive user interface.

- Ergonomic workplace. Pleasant conditions for your employees.

- Outstanding machine availability and reliability thanks to low failure rates, low maintenance requirements, and fast spare parts supply.

- Solid wood

- Wooden panels

- Sandwich panels

- Insulation materials

- Panels made from various insulating materials

- Aluminium

- Plexiglas

If the material you would like to process with our machine is not listed, please contact us! We will find a solution.

Do you have a very specific idea of how your machine should be configured or a special area of application? We will be happy to advise you at your premises to discuss the ideal equipment line and suitable options.

Just one click for an initial consultation!

We are happy to offer you the opportunity to arrange a direct and non-binding initial meeting for a technical consultation by phone or video call. Please use the opportunity to enter an appointment of your choice in the calendar under one of the following options. We will be happy to get back to you and look forward to talking to you!

References.

Customer satisfaction. Our motivation.

Gallery.

Special requests?

Thanks to numerous projects in the field of special machine construction, we are also the right partner for you if your request deviates from standard products. Please feel free to contact us. We look forward to receiving your inquiry!